Rubber Industry

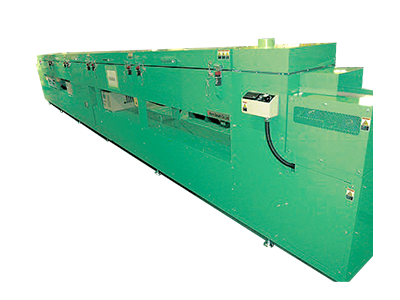

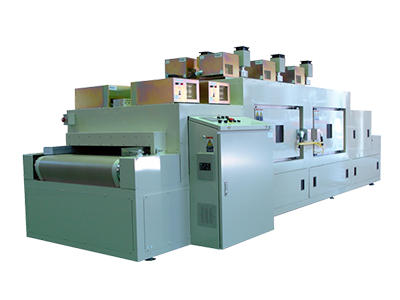

Microwave Vulcanization Tunnel

Our Microwave Vulcanization Tunnel is the industry’s top brand, occupying the No.1 market share in Japan. It also enjoys the highest reputation abroad, and is exported to over ten countries and regions, mostly China, Southeast Asia, and North America.

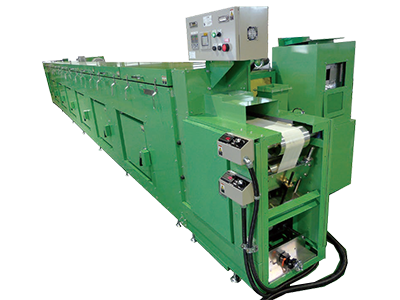

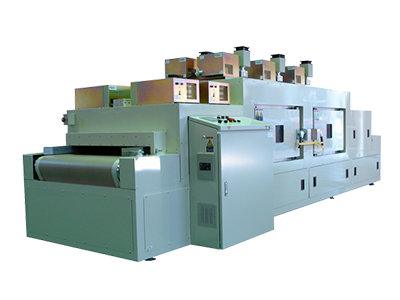

Hot Air Vulcanization Tunnel

The Hot Air Vulcanization Tunnel (HAV) is used as part of the Microwave Vulcanization Tunnel to rapidly increase the temperature of rubber products in order to efficiently complete the required vulcanization.

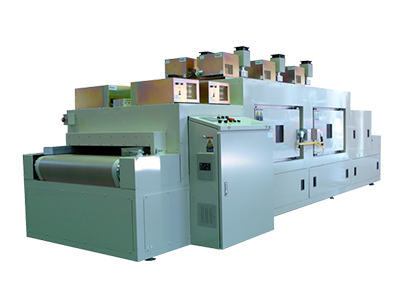

High-Speed Hot Air Microwave Vulcanization Tunnel

The High-Speed Hot Air Microwave Vulcanization Tunnel works like the HAV and Microwave Vulcanization Tunnel combined into one unit. Choose this system when one vulcanization unit is not sufficient for your production line, but there is not enough space to install an additional unit.

IR Heater Oven

Install the IR Heater Oven in front of the Microwave Vulcanization Tunnel to rapidly produce a skin layer on the product’s surface, under high temperatures, immediately after product extrusion. This way, you can effectively retain the shape of the product.

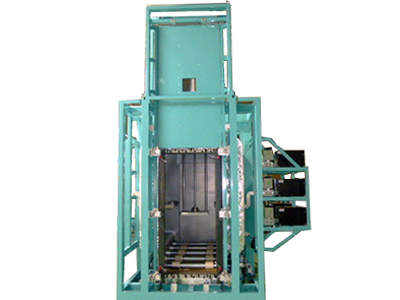

3-Tier Hot Air Vulcanization Tunnel

Sometimes you do not have enough space to secure the required length of the vulcanization line. You can resolve this problem by providing three vertical tiers of conveyors inside the heating tunnel. You can secure the needed time and line length, thus enabling you to effectively vulcanize your products.

3-Tier High-Speed Hot Air Vulcanization Tunnel

This is the higher-specification variation of the 3-Tier Hot Air Vulcanization Tunnel. By using two vertical heating tunnels, you can set different temperatures for the first and second heating tunnels. The first tier is always a high-speed vulcanization tunnel.

Pre-Shock Oven

The Pre-Shock Oven blasts high-temperature, high-speed hot air at rubber products to facilitate vulcanization. It also helps to form a skin layer on the rubber’s surface, thus preventing deformation caused by dripping.

Rubber Pre-Heater

You can apply microwaves to quickly heat the raw rubber to a pre-specified temperature to facilitate the mixing and distribution of additives.

Ceramics Industry

Honeycomb Dryer

Hot-air dryers only dry the products’ surface. It has not been possible to heat and dry honeycomb structures. However, heating with microwave energy allows simultaneously drying both the surface and the interior, thus allowing greater productivity at a more rapid pace.

Water Purifier Filter Dryer

The use of microwave energy shortens drying time, while retaining the product’s shape and configuration. This contributes to increasing your productivity.

Ferrite Dryer

You can dry and harden ferrites, composed mainly of oxidized iron, with microwaves before sintering it to ceramic.

Food Industry

Tea Leaves Roaster

While a general roasting process applies heat from the outside and transmits the heat to the interior to raise the temperature of tea leaves, microwaves allow internal heating. This shortens the heating time, more effectively preserving the flavors, good taste, vitamins, and other ingredients.

Raw Bean Sterilizer

You can heat raw beans during the bean sprout production process in the most effective manner with microwaves, hot air, and steam. This keeps the bean cells intact, while killing off the microbes adhering to their surface.

Instant Noodles Dryer and Inflator

Unlike the usual heating process of applying heat from the outside and transmitting it to the interior, microwave energy allows quick heating of the noodle’s interior. This reduces the drying time and enhances the swelling of the food product.

Sesame Roaster

Different from the usual sesame roasting process of applying heat from the outside and transmitting it to the interior, microwave energy allows quick heating of the product’s interior.

Candy Ingredients Dissolving Equipment

Unlike the usual process of applying heat from the outside and transmitting it to the interior, you can use microwave energy to quickly heat and dissolve or melt the ingredients used to make candies and other sweets.

Rice-Based Snack Foods Dryer

Different from the usual process of applying heat from the outside and transmitting it to the interior, you can use microwave energy to quickly heat the ingredients used to make rice-based snacks. This process can inflate some ingredients and develop new textures and tastes. This can lead to the development of new food products.

Casting Industry

Sand Molds Casting Dryer

This mold dryer reduces drying time, while carefully retaining the original shape and configuration of the sand molds. This will lead to greater production efficiency.

3D-Printed Items Heater

Customers can use our Microwave Continuous Heating Tunnel to dry the various 3D-printed items.

Medical Industry

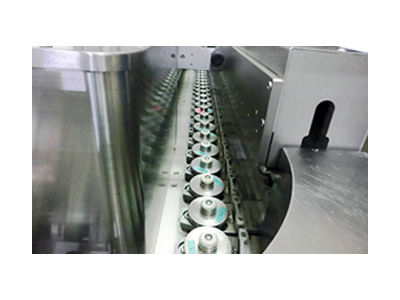

Ampoule Sterilizer

You can install a microwave heater onto the ampoule transport line to sterilize those being transported.

Hollow Fiber Membrane Dryer

In the medical hollow fiber membrane module production, you can apply microwave energy to dry and sterilize the membranes.

Other Uses & Applications

Buckwheat Shell Insecticidal Equipment

When making Japanese-style buckwheat shell pillows, the industry requires heating the buckwheat to kill off insects and their eggs. With this Microwave Continuous Heating Tunnel, you can place buckwheat shells directly on the conveyor belt to continuously disinfect them in just 1-2 minutes. By replacing the general practice of steam heating with microwave heating, you can greatly reduce the heating time. This has many benefits, e.g., reduced heat levels in the working environment, smaller machinery installation space, and decreased manpower, just to name a few.

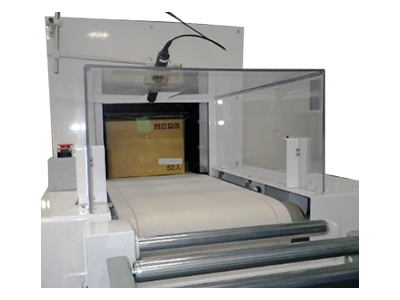

Optical Disc Data Destroyer

You can apply microwaves onto the cardboard boxes or packages containing optical disks to allow electricity to flow through the thin aluminum top layer used as a reflective coating on the disks. The heat quickly destroys all the data on the disk.

Lumber Dryer

Microwaves are transferred to the lumber’s interior, not just the surface, so any internal moisture is quickly moved to the surface. This allows drying lumber with minimal damage.

Cosmetic Ingredients Dissolution Dryer

Unlike ordinary heating which applies heat on the outside, microwave energy heats up the interior of cosmetic ingredients. This greatly speeds up the production process.

Paper Dryer

Microwaves greatly reduce the heating time, while enhancing uniform heating. This leads to a greater ability to mass produce paper and paper products.

Rotating Drum Type Dryer

The rotating drum allows beans, liquids, and other fluid ingredients to be heated by microwave energy. The drum’s interior has been designed and manufactured exclusively for microwave heating; Micro Denshi owns the patent for this structure. When the drum rotates, the workpieces frequently pass through the “void spaces” which can be easily heated with microwaves. This leads to greater efficiency. Even though the drum has a simple structure without any mixing blades, workpieces flow rapidly with natural mixing so they are heated evenly. This is another advantage of this microwave dryer.